System solutions

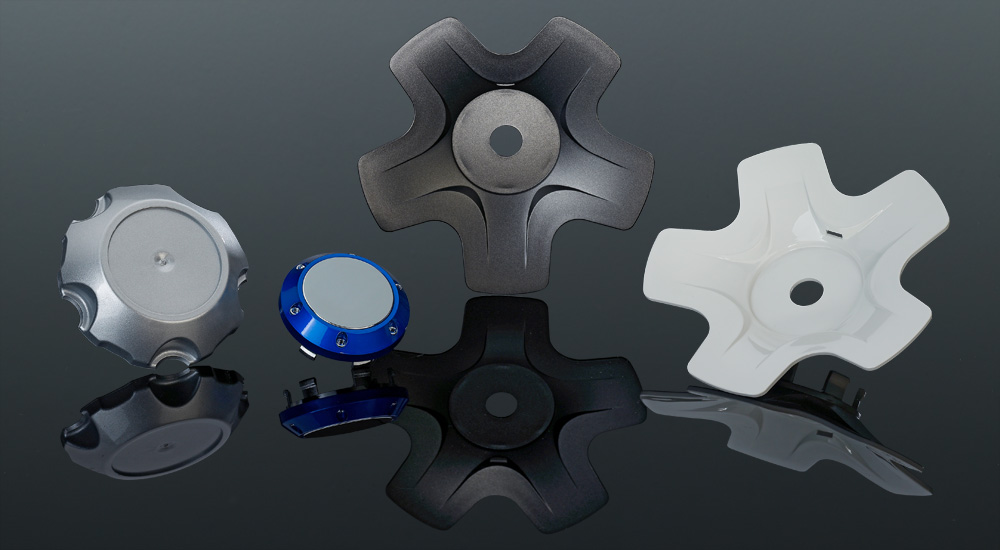

MKT GmbH's range of services also includes the assembling and fabrication of plastic products. Here complete subassemblies and system solutions are manufactured, for example for the automotive industry. MKT GmbH also undertakes the procurement of bought-in parts such as metal components which together with the parts manufactured by ourselves are put together into complete system solutions. In our assembly departments ultra-sound, vibration, heat element and welding processes are employed. In addition 100 % checks are integrated into the production processes. Enhancing/upgrading processes such as printing, chroming, laser-marking etc. are also offered.

Assembly

Our assembly service area augments our range of services for both large and small annual quantities. The individual work steps are efficiently matched one to another. Quality checks that accompany these ensure zero-fault results.

Our assembly service work is carried out in accordance with the particular requi-rements and task in fully or semi automated steps to enable us to offer you a good price-performance ratio.

Laser marking

Taking on an ever more significant role today is the obligation to mark and label products. Within the framework of our activities throughout the world, the traceability of our products is an essential requirement and is offered by us as an additional service. Laser markings in the most different colours or gravures represent just a small example of the possibilities we can offer.

Surface treatment

As a further service we can upgrade / enhance the surfaces of your components.

Depending on the materials used, the component can be electrolytically coated or painted. In addition materials can be mixed in at an early stage in order to achieve the desired finish.

Bi-component surfaces with different textures can be integrated in the mould to give the desired surface feel.

Working in clean, air-conditioned rooms

As a result of the wide range of our product portfolio, investment in clean and properly structured production sequences is essential.

In particular the products for the areas of medicine and food as well as for gear units are subject to the most stringent requirements in terms of cleanliness.

We can verifiably carry out production under the Condition of Cleanliness (VDA 19 as well as ISO 16232).