Series production and commission injection moulding

In a carefully thought out and logical manner we back the most modern and efficient machine technologies.

In a consequent and logical manner we back the most modern and ef-ἀcient machine technologies. More than 30 injection moulding machines with optimum and very comprehensive peripheral devices as well as an appropriate production environment stand ready for you. The efἀcient utilization of our production capacities gives us the Ḁexibility to produce not only in large volume but also in the very smallest batches. At the cur-rent time our machines have locking pressures of from 22 to 130 tons. The shot weights able to be processed range from 0.08 g to 400 g. More than 100 different thermoplastics, our average annual raw material consumptions of which are around 500 tons, are processed by ourselves in accordance with our customers‘ speciἀcations. Our products manu-factured in accordance with the orders of our customers in a very wide range of batch sizes fulἀl the requirements of the most different sectors.

Optimization

We invest in technology and specialist knowledge to ensure that our production environment is always at the latest state of the art. Raw ma-terial is fed to all our machines with the aid of fully automatic conveying systems.

Process stability

We achieve flexibility through the efficient utilization of our production capacities as well as - where necessary - through the logical utilization of those of our diverse long-term and reliable suppliers. In this way we can ensure that your order will progress through our production process in the shortest possible time.

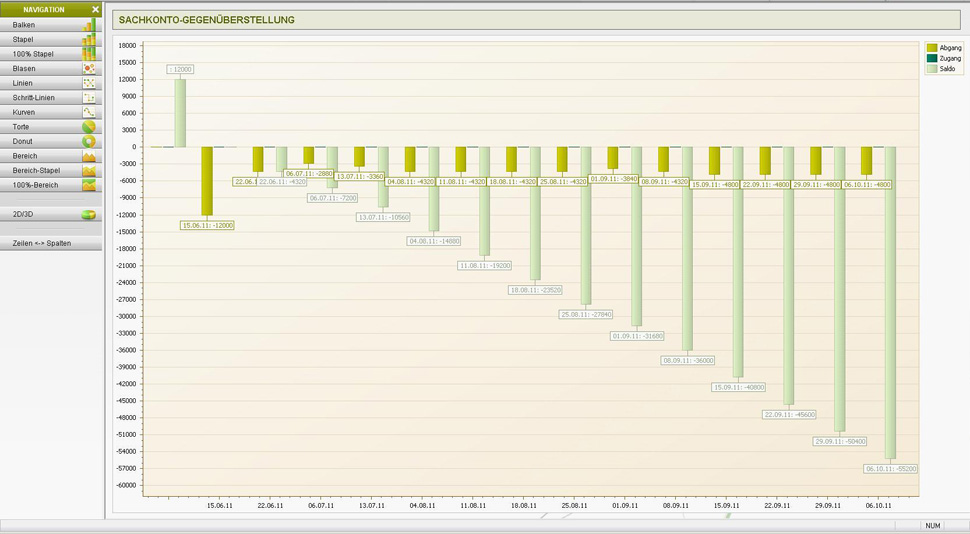

Production planning

We schedule and manage your products using the latest software. From the incoming goods stage to the outgoing goods department the products are channelled, picked and dispatched supported on time - in each case with the appropriate software support.

2-component injection moulding

Innovations and appropriately matched price-performance ratios require new technologies. Where the requirement profiles require this we employ the 2-component technology.

This special process technology employs different materials and combines them in the most different ways in one work operation. Enormous potential for savings and a higher level of component security are the advantages.

Prototype technical release procedure

Before a component is released for series production, it passes through a so-called "Run and Rate" procedure in accordance with the PPAP standard. Here all the relevant characteristics of the component are charted and recorded. In the case of variances the processes and tools are adjusted until full approval for series production is reached (full PPAP).

Regardless of whether a series production order exists or not, we can offer you the prototype technical release procedure to PPAP as a stand-alone service.